website watertownhistory.org

ebook History of Watertown, Wisconsin

Washington Cutlery Co

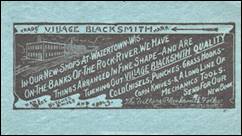

Village Blacksmith

LEFT

WATERTOWN IN 1972

New location for Fisher Barton

Fisher Barton Technology Center

201 Frederick

&

700 S. Water Street

click

to enlarge

WASHINGTON CUTLERY CO

W. C.

Co. stands for "Washington Cutlery Co.," which became Village

Blacksmith, a firm that made cutlery, farm knives and tools from the early

1900s through the 1960s in Watertown.

1906

03 20 MOVED FACTORY FROM MILWAUKEE TO

WATERTOWN

Monday,

representatives of the Washington Cutlery Company were here and a conference

held with the executive committee of the advancement association consisting of

Mayor Wertheimer, Fred Keck, Eugene Meyer, Henry Mulberger, W. H. Woodard, S.

A. Hoffman and Ferd. Schmutzler.

The

committee agreed that in case the company moved its factory from Milwaukee to

this city to raise as a bonus the sum of $3000 which was satisfactory, and work

will be begun at an early day. On Milwaukee street, will be erected a building,

50 x 150 feet, part of which will be one story high and part two stories high.

The

company at the present time employs 30 men and will increase its force when its

new building is ready for occupancy. Twenty of the employees are expert workmen

who will move to this city with their families who will need homes in which to

live and every available home will be taken.

08 21 NEW WASHINGTON CUTLERY PLANT

Work

is progressing rapidly on the construction of the plant for the Washington

Cutlery company on South River Street.

Although work was started only a week ago on the superstructure, the

frame work is well under way and the work is being pushed by Contractor L. J.

Larson of Milwaukee, who is on the ground giving the work his personal

supervision. The plans for the new

factory building were drawn up by O. C. Uehling of Milwaukee. The building is to be 60x144 feet, the front

end and main portion, 60x36 feet to be two stories. Contractor Larson stated yesterday that

according to the terms of his contracts the building is to be completed by Oct.

1st, but he assured a representative of the Leader that his labors would end

before that time . . . The factory, it is expected, will begin operations at

least by the 15th of October and will give steady employment at the start of

about sixty employees, which number will be augmented from time to time, as the

demands of the business will warrant.

1906

05 23 PLANS FOR NEW FACTORY BUILDING

The

news comes from Milwaukee that the gentlemen behind the Washington-Cutlery

Company, which is soon to be removed to Watertown, are actively engaged in

drawing plans for their new factory building on Water Street. The members of the firm are expected here in

a few days to start building operations.

1906

12 06 NEW WASHINGTON CUTLERY PLANT

The wheels of another industry in Watertown will begin their activity

today and contribute to the industrial progress that has been the slogan in

this city for the past few years.

Reference

is made to the new plant of the Washington Cutlery company,

the building for which was recently completed and which is now equipped with

the necessary machinery for carrying on the manufacturing business. A representative of the Leader paid a visit to the plant yesterday and was agreeably

surprised as a result of his observations and believes that there is a great

future in store for the concern ... a trial run of the machinery will be made

today and the factory will start in a small way, increasing throughout the week

and it is expected that by the first of [next] week, everything will be running

full blast. By tonight five of the ten

grinding stones will be ready for action and . . . four trip-hammers ready to

pound away . . .

c.1907

-- -- THE WASHINGTON CUTLERY PLANT

1908

09 15 1908,

U.S. Patent, Villiage Blacksmith, Hugo Volkmann

c.1908

c.1910

SHIPPING DEPARTMENT IN PLANT

ATTACHING WOOD HANDLES TO KNIVES

GRINDING AND FINISHING ON LARGE STONES

1912

03 28 THE TWO ANVIL METHOD manufacturing

process

Before

we made calculations, we were astounded to have it told us that it would take

the Washington Cutlery Company of this city about 50 years to make one of their

High-Grade, Hand-Wrought, VILLAGE BLACKSMITH Butcher Knives for each family in

the United States.

The

company, on account of the home sound of their trade mark-throughout the United

States, are familiarly known as the VILLAGE BLACKSMITH FOLKS.

Their

shop is not remarkable for its large size, these people in fact taking pride in

their limited production of about 150 dozen per day, preferring, as they say,

to make goods for the exacting public, and wanting to retain the feeling that

they had in the starting of their business, with two anvils, that the goods

would always be so good that they could sell them to some particular friend,

whom they didn't want to disappoint.

The TWO

ANVIL METHOD, as it is referred to, is still followed out in its essential

processes. In the beginning a workman

took out a bar of steel and returned the finished knives, but now with its half

a hundred workmen, the business has been systematized so that the work is

passed on from one workman to another, each one, who has become proficient in

one special operation, thereby enabling the company to have a much more uniform

product as to style and finish, than was formerly the case, and has also enabled

them to manufacture their goods so as to be able to sell them within the reach

of more people.

We

were very much surprised to see their nicely finished Hand Wrought Knives that

had been ground on the old time sandstone, tempered by the old oven method, and

whetted to a keen useable edge, that could be sold as low as 50 cents for a

nice house knife.

Having

visited large automatic producing eastern knife factories, we were very much

struck by the thoroughness and the care given the goods, going through the

VILLAGE BLACSMITH shop.

We

were shown through the various rooms by Mr. Hugo Volekmann,

one of the founders of the business, and by the way, this family has lived here

since 1850, and we are pleased to note from his conversation, that the

company's customers were scattered throughout the United States, and that

letters from interested customers, addressed to "The VILLAGE

BLACKSMITH" promised the necessity of larger output soon. WGazette

c.1912

1913

01 02 NEW POWER BUILDING AT THE PLANT

Last

week Tuesday thirty-five employees of the Cutlery Co. enjoyed a smoker and

luncheon in the

new power building at the plant.

Speeches were made by J. B. Radford and Otto Steinagel, and quartette

singing was rendered by Emil Rehbaum, Bert Hadley, Henry Lueck and Abe

McKinney. WG

1914

03 31 1914,

U.S. Patent, Villiage Blacksmith, Hugo Volkmann

1915

10 07 INJURED

IN AUTO ACCIDENT

While

driving a Ford car on the Plank Road about three miles west of this city last

Thursday afternoon Hugo Volkmann, secretary and treasurer of the ., had one of his legs badly torn by his

machine turning turtle. Edward Maldaner

was in the machine with him at the time, but escaped injury. The machine turned a complete somersault, the

four wheels thereof pointing heavenward, as the two men crawled from under the

machine. They certainly had a miraculous

escape. Farmers who witnessed the

accident rushed to the scene and were greatly surprised that a more serious

accident was not the result of the tipover.

A passing autoist brought Messrs. Volkmann and Maldaner to the city, and

employees of a local garage brought the Ford to the city. It was not very badly damaged. WG

1917

Jefferson County

WI and its People

Prominent

among the industrial concerns of Watertown is the Washington Cutlery Company,

which was incorporated in 1906 with a capital of thirteen thousand.

The

company manufactures the "Village

Blacksmith" brand of butcher knives, cleavers, tools, corn knives,

sickles, cold chisels, screw drivers, punches, etc., and their products are

sold principally in the United States.

They

furnish employment to from fifty to sixty hands, fifty per cent of whom are

skilled workmen. Their plant has a floor space of sixteen thousand square feet

and is supplied with the latest equipment, being remodeled, enlarged and new

machinery being installed in 1917.

The

equipment now includes automatic grinding machines, forges burning fuel oil,

oil tempering machines, punch presses and trip hammers, all of the latest

design and the best to be found in the market.

The

business has grown rapidly and the plant is now behind in its orders.

The

officers of the company are Gustave H. Lehrkind, president and sales manager;

Charles Richenbaum, vice president; and Hugo E. Volckmann, secretary, treasurer

and manager. They are all men of long experience in metal manufacturing and

their plant is one of Watertown's prized assets.

________________________________________________________

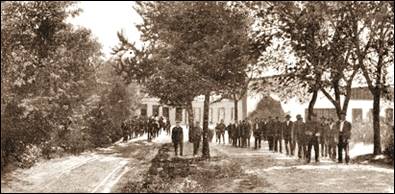

1921

Watertown High School Orbit

Noon

Hour at Village Blacksmith

click

to enlarge

The

Village Blacksmith Folks have been established over twenty-five years and up to

twelve years ago were located at Milwaukee. The shops were removed to Watertown

because of the superior advantages of this city, and the energetic solicitation

of the Watertown Advancement Association.

From time to time additions have been built, and it is planned to

develop the plant still farther, when normal and stabilized business conditions

warrant it.

Since

its establishment, no changes have taken place in the ownership or officers of

this company, who are: G. H. Lehrkind, President; H. E. Volkmann, Secretary and

Treasurer, and Charles Reichenbaum, Vice-President.

In the

early years, only a limited line of Household Knives was made. The output at

this time was only ten to fifteen dozen per day. The knives were sold to the

retail stores in Wisconsin.

The

product now consists of Knives, Cleavers, Grass Hooks, Corn and Hedge Knives,

Screw Drivers, Chisels, Punches, Draw Shaves, and other tools. All of these are

high quality goods, and the production reaches some 700,000 pieces annually,

which are sold in more than 3,000 hardware stores, as well as in Restaurant and

Butcher Supply, Auto Supply, and in Seed and Implement Houses throughout the

United States.

Jobbers

take care of the major portion of the distribution under the trademark: “The

Village Blacksmith Folks.”

The

goods which are listed and illustrated in a large number of catalogues are

estimated as follows:

120,000

in Hardware Lines.

10,000 in Butcher and Restaurant Supply

Lines.

25,000 in Auto Supply Lines.

200,000

in Seed and Implement Supply Lines.

The company

maintains a western selling and distributing branch at 731 Market Street, San

Francisco, as well as a local agent at Chicago.

1931

1934

03 26 KNIFE FOUND ON BATTLEFIELD IN FRANCE

A

knife made in Watertown was recently picked up on a battlefield in France. It went the rounds of the State Capitol at

Madison on Thursday when Superintendent of Public Property, M. F. Blumenfeld

exhibited it. The knife was sent to Mr.

Blumenfeld with a section of a German airplane wing which was found on the same

field and the mark on the knife read, "Made by the Village Blacksmith,

Watertown, Wisconsin."

c.1940s

Uncertain date

c.1950

-- -- CUTLERY FIRM HAS GAINED RENOWN

WDTimes profile of the

company

For centuries

past, Toledo, Spain, and Damascus, Syria have been noted for the excellent

quality of their steel implements and the careful workmanship which went into

the swords and blades turned out in their shops.

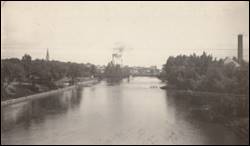

Watertown,

too, has a concern that has achieved similar renown. It is the cutlery plant which for many years

was known as the Village Blacksmith Folks, but which now goes by the name of

Village Blacksmith Co. It is housed in a

rambling plant which sprawls on the west shores of Rock river.

The

Village Blacksmith Co. has operated in Watertown since 1907. At that time the old Watertown Advancement

Association induced the concern to move from Milwaukee to Watertown. The firm had been operating in Milwaukee from

the time of its founding in 1894. The

firm then was known as Lehrkind, Davil Co., but two years after the

organization was launched it became the Washington Cutlery Co., using the

brand, “Village Blacksmith” on its products.

The company makes cutlery of all kinds, including garden tools.

Hand-Wrought

Products

The

term “Village Blacksmith” was selected because it was felt to be a fitting

description of the forged, hand-wrought products of the concern. From 1907 to 1920 the factory operated under

the title Washington Cutlery; then the corporate name was changed to Village

Blacksmith Folks, retaining the blacksmith brand.

The

factory is unique in that newer methods of manufacture have been introduced

only when the quality of the product was not impaired thereby. The company never has gone in for hurried or

stepped up production, but has maintained a policy of careful work down to the

most minute detail.

Today

its products are sold all over America.

They include professional and household cutlery and cleavers. Thousands of the latter were manufactured

during the war for the quartermaster corps of the Army.

Officers: Roy M. Henry, president; Henry Winogrond,

vice president and treasurer; and Joseph N. Grinnell, secretary.

1952 FIRE

RAKES PLANT

Village Blacksmith Co. to rebuild

after fire rakes plant on 07 25 1952

1952

07 26 FIRE RAKES

PLANT

Officials of the

Village Blacksmith Company, manufacturers of cutlery and garden tools,

announced here today they plan to rebuild as soon as possible the forge unit of

their plant which was swept by a $50,000 fire last night. They said 90 men are employed at the

plant. They hope to be in full operation

at the earliest possible time.

The fire, which broke

out sometime before 9:30 p.m., was reported by telephone to the City Hall by

Mrs. Joseph Stacy, 615 South Washington Street who told the Police Department

that the building was on fire, that there was a lot of noise in the place and

she could “hear” the fire. The message

was relayed to the Fire Department immediately and all available equipment was

sent to the plant on Frederick Street, near the banks of Rock River. Firemen fought the blaze until 2:30 a.m. It was the worst fire in the city since the

$50,000 Savoy theatre building blaze on June 6,

1950.

Blast Suspected

The fire is believed to

have started in a minor heating unit of some of the equipment in the forge

shop. The blaze set off the automatic

sprinkler system. The forge shop is located

in the newest part of the plant, erected some years ago directly to the rear of

the company offices. A blast of some

kind is suspected.

Fire Chief Al Linde put

in a call for help to Oconomowoc, Ixonia and Lebanon Fire Department, all of

which responded with one truck each.

The fire reddened the

sky and it could be seen for miles. The

smell of smoke filled the air over the city and it was noticeable as far as

three miles away near the northeastern limits of the city.

The fire attracted one

of the largest crowds at any here in years.

Not only did Watertown residents rush to the spot, but people from

surrounding farm areas and nearby localities were attracted by the blaze. There were many people from Oconomowoc in the

crowds that milled about.

Chief Linde said he

wanted to commend the Police Department for the way it handled the crowd. The crowds were kept pretty well back on the

whole so as not to interfere too much with the fire fighters. All available police helpers were called out

and all volunteer firemen also were on hand to augment the regular department

members.

Fireman Injured

On fire fighter,

Francis Pirkel, 38, was injured. He

suffered severe hand lacerations. He

lives at 602 Lafayette Street.

The estimate of damage

was made by Chief Linde who said it was entirely unofficial. Officers of the company would place no

definite estimate on the possible loss, but said it will be heavy. However, they announced that several large

presses used in the forge department appeared undamaged and Fire Department

officials said they believed the ovens also escaped major damage.

Damage to much of the

plant is great. There was much damage by

water and smoke, in addition to the actual blaze damage. Firemen said that the fire would have been a

major disaster if the blaze had reached the paint and chemical supplies used in

the plant.

No One on Duty

There was no one

working in the place at the time of the fire.

It has no regular night watchman but is served by the Merchant

Police. Everything appeared in order

when the last check was made. The fire -probably started suddenly, if it was a

blast of any kind that set it off, as appears likely.

The company was founded

in Milwaukee in the 1890’s and operated there for some 12 or 15 years before it

relocated, moving to Watertown about 1908.

It was brought here largely through the efforts of the Watertown Advancement

Association, which was then active in the city’s industrial development.

In its early years the

company made a product known as Household Knives. The output in the early years was only ten to

15 dozen per day. The knives were sold

to retail stores in Wisconsin.

The company, as it

expanded, added knives of all kinds to its products. Clevers,

grass hooks, corn and hedge knives, screw drivers, chisels, punches, shaves and

other tools were among products that were manufactured at various times.

In recent years the

company has turned out a widely known line of fine cutlery and garden tools.

By 1921 the company was

turning out between 700,000 and 1,000,000 individual pieces annually. Its products were sold by more than 3,000

hardware stores as well as in restaurant and butcher supply stores throughout the

United States.

In addition to its

present products, the company also does some small contract order work and it

has also been doing some work under defense contracts.

During its years in

Watertown two of the men here who played a large part in developing the concern

were the late G. H. Lehrkind, who was for many years its president, and the

late H. E. Volkmann, its secretary and treasurer. The late Charles Reichenbaum of Milwaukee was

for many years its vice president.

Current officers of the

company are R. M. Henry, president; Joseph Roti, vice president; Joseph

Calderini, secretary.

For many years the

concern was known as the Village Blacksmith Folks, but in recent years the name

was changed to the Village Blacksmith Company.

07 27 DEMOLITION AT

BLACKSMITH CO. TO START HERE

Demolition and salvage

work at the fire-swept plant of the Village Blacksmith Company will begin

tomorrow or Wednesday, C. M. Towne of the company told the Times this morning. He said

an insurance check is still being made and when that is completed work on

clearing away the debris and paving the way for rebuilding and repairs will be

undertaken. Mr. Towne said the plant

carried full insurance.

1954

12 16 OFFICERS AND DELEGATES ELECTED

Officers

and delegates were elected this week in Watertown by Machinists Local No. 1367

of the International Association of Machinists, AFL, it was announced today.

The local represents the Parts Engineering Co., the Village Blacksmith Co., the

Otto Biefeld Co., the Syncromatic Corp., the Kusel Dairy Equipment Co., and the

Brandt Automatic Cashier Co., all of this city. The following officers were

re-elected: Kurt Rex, president; Eric Loeffler, vice president; George

Havlicek, treasurer; Fred Harder, financial secretary; Roland Schauer,

recording secretary; and Melvin Gruenewald, sentinel. WDT

1956

03 17 50th

ANNIVERSARY

The

Village Blacksmith Company this year is observing the 50th anniversary of

operation in Watertown, Henry Winogrond, head of the firm, told the Rotary Club

at its noonday luncheon. The firm actually was established 62 years ago, he

said. It was founded in Milwaukee as the Washington Cutlery Company. The plant

moved its operations to Watertown 50 years ago. Mr. Winogrond commented on the

changes in buying habits and living standards of the American people which has

resulted in changes in items manufactured by the firm since World War II.

Professional cutlery has become an important item at the plant. This line of

knives and other cutting equipment is sold to meat packing houses, hotels and

restaurants, and in recent years this phase of the business has become more and

more important. More people eating out, he said, is to a large extent

responsible for the growth of this phase of the business.

09 26 RESIDENTIAL

MAIL BOXES

A Watertown merchant and a Watertown

manufacturer have combined talents to provide the community with an example of

products “Made in Watertown - Sold in Watertown.” The result is currently on display at 220

South First Street, the Hutson-Braun Lumber Co. It is here that the Hutson-Braun Lumber Co.

has designed a complete display window for the showing of Village Blacksmith's

new line of “Galaxy Letter Boxes.” Local

residents had a preview of these residential mail boxes last spring at the

Jaycee Industrial Fair at the National Guard Armory. Since that time they have been acclaimed as

the most beautiful line of home mail boxes produced anywhere in the

nation. WDT

1969

07 01 REPORT

ON TRIP TO JAPAN

Henry

Winogrond, vice president and general manager of the Village Blacksmith Corporation,

gave a report and some observations on a recent business trip to Japan and

other countries in Asia at this week’s meeting of the Watertown Rotary Club,

held at the Green Bowl. Japan, he said,

is moving ahead extremely rapidly. “The

are working hard and are way past the copying stage,” he stated. He said he commented to people in Japan on

the rapid changes, and the great progress.

They answered by saying that for 20 years progress had not been slow

because the United States had held an umbrella over them.

1972

05 13 VILLAGE BLACKSMITH IS LEAVING

WATERTOWN

Plans

to transfer the operations of the Village Blacksmith Division of McGraw-Edison

Company from Watertown to Jefferson City, Mo., were announced by company

officials in Elgin, IL., home of the parent firm.

The

Watertown plant, which employs approximately 150 persons, is located at 201

Frederick Street and has a plant located at 1012 South Third Street.

McGraw-Edison

officials said the move was dictated by the changing character of the lawn and

garden tool market where the emphasis is now on electrical products.

Jefferson

City, Mo., is McGraw Company’s major manufacturing facility for electrical

power tools of all kinds. The company also has five other electrical products

plants in close proximity to Jefferson City.

The

transfer of the Village Blacksmith operations will take place during the late

summer and early autumn, officials said. Some of the present personnel will be

offered positions with the firm in

its

new location.

Henry

Winogrond, an official with the firm said the firm, which is nearly 70 years

old, has seen a gradual change in its product lines over the years. He said

much more of the equipment in its lines are being made to operate with

electricity and the number of tools operating without electricity is becoming

less and as a result the local business will be moved to Jefferson City, Mo.,

where the electrical units are manufactured.

1990

03 24 VILLAGE BLACKSMITH NAME RESURRECTED

Dick

Davis, a Los Angeles businessman who has resurrected the Village Blacksmith

name, owns a firm called SMS Industries.

Some years ago Village Blacksmith was sold to McGraw Edison and later it

was sold to Shopsmith, an Ohio firm.

Then about five years ago, Davis and his associates purchased the

Village Blacksmith name and began manufacturing and marketing some of the

original Village products under the Village name.

The

firm has been marketing basically in the west coast area, making hedge shears

and basic garden tools. More recently the firm expanded into the agricultural

field, specializing in tools for vineyards and orchards.

Davis

said business has been good, but has really taken off with the firm’s newest

product. Originally it was called a

“landscaper’s blade” which was designed to cut off tap roots from bushes and

shrubs. The bad news is that almost no

one uses it for that purpose, but the good news is that it’s used for

everything else imaginable. “The

response has been incredible. Some

people say it’s the best ice scraper on the market. Others use it as a paint scraper, and some

use it to remove asphalt.”

WDTimes

of 03 24 1990. “In Times Square /

Village Blacksmith Recalled.” In Village

Blacksmith collection

1990

08 08 PHILIP

A. PARMLEY

Although

Philip A. Parmley will take over as president of Fisher-Barton Inc. this month,

succeeding Richard Wilkey in that position, no major changes in leadership are

expected. Parmley, currently vice

president of manufacturing functions, has been with Fisher-Barton since its

beginnings in 1973, so his role with the firm has been a continuous one. And Wilkey will continue his ownership role,

although he will phase out his day-to-day involvement. Given the firm’s success, a shake-up

certainly isn’t warranted. Parmley said

business at the company is as good as it ever has been during his 17 years at

Fisher-Barton. “I can’t recall a time

when we’ve ever been caught up,” he said.

“We have a half-million pounds (of metal) to do this month and we’ll

have to push to do it.” WDT

1993

06 23 LARGEST

MANUFACTURER OF CARBON STEEL LAWN MOWER BLADES IN THE WORLD

Local

homeowners sweating behind their lawn mowers should feel a sense of civic pride

when cutting the lush lawns produced by recent rains. Chances are the grass is being cut by a lawn

mower blade made in Watertown. Forging

ahead with new ideas has kept Fisher-Barton Inc. of Watertown heading up the

sales charts to become the largest manufacturer of carbon steel lawn mower

blades in the world. The recent addition

of a new press and a new plant will help the company keep its lofty status on

top of two other companies which are its only other major competitors. Fisher-Barton makes too many blades to count

by number -- output is measured in pounds.

The company has orders for a record 600,000 pounds of steel blades to

make in July which is usually a slow month.

Business used to be so slow in July that the company shut down for two

weeks. Now it must push to keep up with

orders. Most of the thousands of pounds

of residential and commercial blades ranging 10 to 33 inches in size have

already left the plant in time for the summer grass-growing season. The company has outgrown its

35,000-square-foot plant at 201 Frederick St. and added a new plant on eight

acres off South Twelfth Street which houses a new punch press capable of 1,000

tons of pressure. A large part of the

company's growth over the last 20 years is credited to Philip A. Parmley, 63,

who was recently promoted from president to chairman. Parmley has seen the company grow from a

small, rented shop with used equipment to one with two plants and 170

employees. WDT

2013

05 15 FIRE

AT FISHER-BARTON

![]() Fire at Fisher-Barton,

portion of the former Village Blacksmith building.

Fire at Fisher-Barton,

portion of the former Village Blacksmith building.

06 28 NEW

GLOBAL HEADQUARTERS & MOWER BLADE OPERATION

Fisher Barton Blades, part of The Fisher Barton Group, announces the relocation of

their Watertown, Wisconsin lawn mower blade operation and global headquarters,

into a larger modern 90,000 square foot facility located adjacent to the

Watertown airport.

The

new facility doubles manufacturing space to accommodating the company’s

continued growth and allows Fisher Barton Blades to provide even more value to

the turf care and lawn & garden equipment OEMs it serves, with expanded

product packaging and direct order fulfillment services.

“The

former Fisher Barton Blades manufacturing plant had some areas that were more

than 90 years old,” said Shane Bonner, Fisher Barton Blades president. “The

plant grew with the company over the years, requiring multiple additions that

resulted in a disjointed and inefficient floor plan. The facility just did not

lend itself to modern manufacturing methodologies such as cellular

manufacturing and in-line flow. These challenges, coupled with our OEM

customer’s requests to assist with order fulfillment and distribution,

motivated us to consider other locations. We were very pleased to find an

existing building located in Watertown, just two miles from the former

facility.”

The

decision to remain in Watertown reaffirms Fisher Barton Blades’ four-decade

commitment to the community and retains 65 family-sustaining jobs.

Fisher

Barton Blades, the world’s largest producer of lawn mower blades and part of

The Fisher Barton Group, has been producing high quality blades and wear

components for the turf care and lawn & garden equipment industry’s leading

OEMs for over 40 years. In addition to

this manufacturing facility and global headquarters in Watertown, they also

have a second 94,000 square foot manufacturing facility in Fountain Inn, South

Carolina.

2015

09 09 FISHER BARTON’S NEW

TECHNOLOGY CENTER

click to enlarge

Fisher Barton has renovated its facility at 201 Frederick St. for its

new state of the arts technology center to focus on innovation and process

development.

Having once housed the Village Blacksmith, Fisher Barton has taken

many precautions to preserve the history of the building while adding the

center adjacent to the shipping and receiving areas. It blends old with new. Trying to preserve as much as possible of the

old character of the building created a lot of challenges for construction and

design. The time and effort in

preserving the building is evident, with the building’s original bricks

aligning rooms and old massive beams supporting the very spacious office and

meeting rooms. One of the beams from

the middle of the building was moved but saved and counter tops were made out

of it. WDTimes

article

The

center is Fisher Barton's third location in Watertown. For more than four decades, Fisher Barton has

operated in Wisconsin, beginning with a 2,400-square-foot rented building in

Oconomowoc in 1973. The company outgrew

that building a year later, and relocated to the former Village Blacksmith

location on Frederick Street in Watertown.

It was from this location that Fisher Barton Blades operated for the

next 40 years. In 2013, Fisher Barton

Blades moved from Frederick Street to Air Park Drive, and in doing so, doubled

its manufacturing space. Then, late last

year, the company began renovations for the new technology center. The center currently has 12 employees.

12 11 WEDO HONORS FISHER BARTON

Fisher

Barton and Richard and Susan Wilkey, founders, were awarded the Watertown

Economic Development Corporation Community Impact Award for the company's work

in revitalizing its facility on South Water Street into a state of the art

Technology Center and their commitment to Watertown. WDTimes

article

2016

09 15 FISHER BARTON NAMES GROUP

PRESIDENT

Fisher Barton announced Wednesday the appointment of Igor

Zelenovskiy to the role of group president as of Sept. 6. As group president, Zelenovskiy will have

responsibility for all of the company’s operating units worldwide. He will build on the solid foundation and

momentum achieved by the Fisher Barton team under former Group President Greg

Wilkey’s leadership and will be responsible for driving Fisher Barton’s future

growth initiatives. Zelenovskiy joined

Fisher Barton in 2014 as president of the Fisher Barton Technology Center here

in Watertown. During his tenure with the

company, he successfully helped establish the state-of-the-art technology

center — a long-term vision for the Fisher Barton Group. Under his leadership,

the company engaged in the development of new products and processes to

accelerate Fisher Barton’s growth.

An accomplished leader, Zelenovskiy has a track record of

working with high-growth companies.

Prior to joining Fisher Barton, he served in various leadership

positions with Rexnord Corp., Joy Global and Rockwell Automation. In addition to his technical experience,

Zelenovskiy has extensive experience in product marketing and sales.

Zelenovskiy earned a Master of Science degree in manufacturing

engineering management from the University of Wisconsin-Milwaukee and a

Bachelor of Science degree in electromechanical engineering from Donetsk State

Polytechnic University, Ukraine.

2017

07 21 FISHER BARTON TO ADD 80

POSITIONS IN WATERTOWN

Milwaukee Journal Sentinel online article

2021

07 21 BONUS AWARD PAYMENT FOR

EMPLOYEES

Fisher Barton awards bonus payment Fisher Barton, a leading

metallurgical science company that develops high wear and cutting components,

announced a bonus award payment for all US-based employees.

The bonus payment of $1,250 will be distributed in mid March and represents the company’s gratitude for the

employee support and commitment to serving customers during the recent pandemic

and time of disruptive business conditions.

Fisher Barton based in Watertown, is a metallurgical science

innovation partner for high wear and cutting components. Its expertise stems from its employees who

understand the behavior of material and the application of proprietary heat

treating and thermal spray solutions that reimagine a component’s lifespan

beyond the core manufacturing capabilities of stamping, bending, forming,

cutting, welding, machining and casting.

The company has eight locations in Wisconsin, Illinois, and Vietnam that

manufacture innovate blades and turf care components, bronze motion control

products, industrial knives

and various other wear components.

09 29 NEXT-GENERATION

INDUSTRIAL BREAKING TECHNOLOGY

WATERTOWN, WI <> Fisher Barton a

metallurgical science innovation company, releases its Multi-Disc Tension Brake

System at the 2021 Utility Expo in Louisville, Kentucky. Designed specifically for utility construction

applications, the next-generation brake system is engineered to provide smooth,

consistent braking with higher torque and cooler operating temperatures. The three-point design provides consistent

braking tension-reducing pulses and surges on the line. The aluminum-bronze composite rotor radiates

heat away from the braking surface better than solid bronze rotors improving

thermal conductivity, creating longer pad life, and decreased maintenance

downtime. The Fisher Barton Multi-Disc Tension Brake Systems easily mounts to

trailer systems and reel stands.

10 13 FISHER BARTON PERFORMANCE

PLAZA at Town Square

The city’s Town Square recently received

a financial boost to help construct its main stage and lawn seating area, which

will be named the Fisher Barton Performance Plaza. The amount of the donation was not released.

The area encompasses an expansive green space skirted by a naturally landscaped

area with boulder seating. Audiences of

250 or more can enjoy a solo musician, a multi-piece band or dance/theatrical

groups performing on an open air, elevated wood platform. “

Earlier this year, Fisher Barton

sponsored a memorial bench on the Town Square to commemorate the production of

its 300 millionth lawn mower blade and to recognize founder Richard L. Wilke.

Fisher Barton started as Washington Co.

Cutlery, relocating from Milwaukee to Watertown in 1906. By 1910, it employed between 50 and 60

people. In 1974, Fisher Barton started manufacturing

lawn mower blades at its original 1910 location. In its 111-year history, Fisher Barton has

led the industry by establishing the first metallurgical lab for research,

patenting steel technology and production of more than 300 million lawn mower

blades. Fisher Barton employs 144 people

at its Watertown locations.

2023 50TH ANNIVERSARY YEAR

http://www.wisbusiness.com/2023/fisher-barton-celebrates-50-years-of-innovation-and-excellence/

09 27 LAWN MOWER BLADE: CONTENDER IN COOLEST THING MADE

Watertown, WI – – Fisher Barton, the world’s leading

manufacturer of lawn mower blades, is

thrilled to announce that its innovative LaserEdge

Lawn Mower Blade has been selected as

one of the Top 16 contenders in the prestigious 2023 Coolest Things Made

In Wisconsin contest [link

to press release]

Cross-References:

Prior

to the 1940s the Village Blacksmith name was incised or stamped directly into

the blades of cleavers.

Afterwards it was stamped on the handles.

Architecture

and History Inventory report

![]()

History of Watertown,

Wisconsin